Fuel Tank Fabrication – Custom Solutions by Fabrimech

Introduction

Fuel storage requires precision engineering and high-quality materials to ensure safety, durability, and efficiency. When it comes to fuel tank fabrication, choosing the right manufacturer is crucial to meet industry standards and regulatory compliance. Among the top names in the industry, Fabrimech is a trusted leader in designing and fabricating premium fuel tanks for various applications, including industrial, commercial, and transportation sectors.

Why is High-Quality Fuel Tank Fabrication Important?

Proper tank fabrication ensures safe storage and transport of fuels such as diesel, petrol, and aviation fuel. A well-fabricated tank prevents leaks, corrosion, and structural failures, reducing environmental risks and improving operational efficiency. Leading manufacturers like Fabrimech use advanced fabrication techniques to produce tanks that offer long-lasting performance and reliability.

Key Features of Fuel Tank Fabrication by Fabrimech

High-Grade Materials

Advanced Welding Techniques

Custom Design & Fabrication

Corrosion & Fire-Resistant Coatings

Compliance with Industry Standards

Tanks made from stainless steel, mild steel, and aluminum for maximum durability.

Ensuring strong, leak-proof joints

Tailored solutions for various fuel storage requirements.

Enhancing tank longevity and safety.

Adhering to ISO, ASME, and API specifications.

Types of Fuel Tanks Fabricated by Fabrimech

As a leader in fuel tank fabrication, Fabrimech provides a variety of fuel storage solutions, including:

Underground Fuel Tanks

Above-Ground Fuel Tanks

Double-Walled Fuel Tanks

Custom-Built Fuel Storage Tanks

Mobile & Transport Fuel Tanks

Space-saving and ideal for long-term fuel storage.

Easy to maintain and perfect for commercial use.

Extra protection against leaks and environmental hazards.

Designed to meet specific industry requirements.

Engineered for safe fuel transportation.

Why Choose Fabrimech for Fuel Tank Fabrication?

Among the top fabrication companies, Fabrimech stands out due to:

Precision Engineering & Fabrication

Custom Solutions for Industries

Safety & Compliance Assurance

Competitive Pricing & On-Time Delivery

Trusted by Leading Industries

Ensuring top-quality fuel tanks.

Serving petroleum, aviation, marine, and transport sectors.

Tanks built to meet regulatory standards.

Cost-effective and timely manufacturing.

Proven track record in high-quality tank fabrication.

How to Select the Best Fuel Tank Fabrication Company?

When choosing a company for tank fabrication, consider:

- Material Quality & Strength – Ensure tanks are made from high-grade, durable materials.

- Welding & Fabrication Standards – Look for advanced welding techniques for leak-proof construction.

- Regulatory Compliance – Choose a company that meets ISO, ASME, and API certifications.

- Customization & Capacity Options – Select a manufacturer like Fabrimech that offers tailored solutions.

- After-Sales Support & Maintenance – Reliable servicing for long-term tank performance.

Conclusion

If you are looking for the best fuel tank fabrication solutions, Fabrimech is your ideal partner. With high-quality materials, precision engineering, and compliance with industry standards, Fabrimech delivers top-tier fuel storage tanks for various applications.

Contact Fabrimech today for customized tank fabrication solutions that meet your industrial needs!

Top Tank Welding Companies – Precision & Quality by Fabrimech

Intoduction

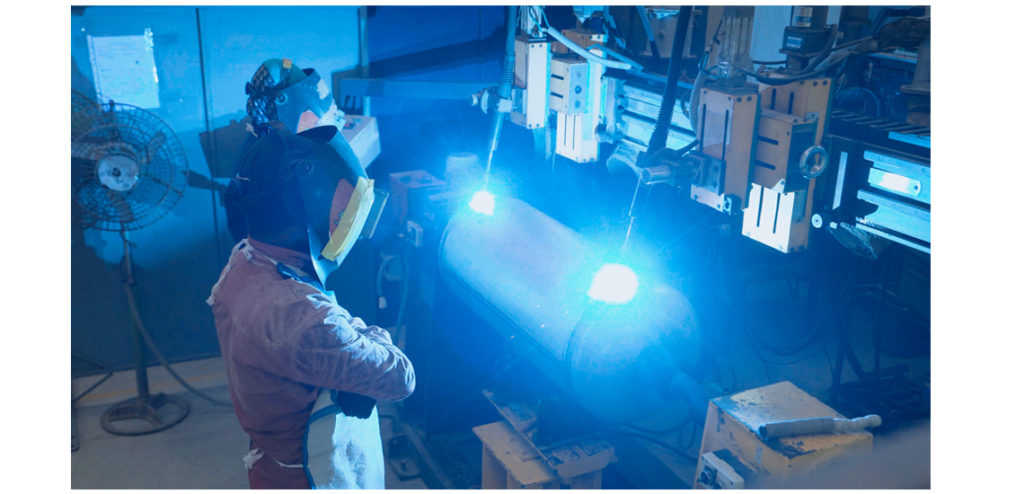

When it comes to industrial tank fabrication, high-quality welding is crucial for durability, strength, and leak-proof performance. Finding reliable tank welding companies in ensures that storage tanks meet industry standards and offer long-lasting efficiency. Among the top names in the industry, Fabrimech is known for its advanced welding techniques and expertise in manufacturing high-performance storage tanks for various applications.

Why Choose Tank Welding Companies ?

Industries such as petroleum, chemicals, pharmaceuticals, and water treatment require precision-welded storage tanks to ensure safety and efficiency. The leading tank welding companies like Fabrimech, offer cutting-edge welding technology and superior craftsmanship to deliver high-quality, corrosion-resistant tanks that withstand harsh conditions.

Key Features of Tank Welding Services by Fabrimech

Advanced Welding Techniques

Leak-Proof & Corrosion-Resistant Tanks

Custom Fabrication

Compliance with Industry Standards

On-Site & In-House Welding Services

Includes MIG, TIG, and arc welding for maximum strength.

Ensuring long-term reliability.

Tailor-made solutions for different industries.

Tanks meet ISO, ASME, and API specifications.

Flexible solutions for various project needs.

Types of Tanks Welded by Leading Companies

Top tank welding companies including Fabrimech, specialize in fabricating and welding various types of storage tanks, such as:

- Stainless Steel Tanks – Ideal for food, pharma, and chemical industries.

- Mild Steel & Carbon Steel Tanks – Durable and cost-effective solutions for industrial use.

- FRP & HDPE-Lined Tanks – Corrosion-resistant and long-lasting.

- Underground & Above-Ground Tanks – Custom-built for specific storage needs.

- Pressure Vessels & Large-Scale Industrial Tanks – Engineered for high-pressure applications.

Why Fabrimech is a Trusted Name Among Tank Welding Companies?

Among the top tank welding companies, Fabrimech stands out due to:

State-of-the-Art Welding Technology

Experienced Welders & Fabricators

Comprehensive Tank Solutions

Affordable & Competitive Pricing

Trusted by Major Industries

Ensuring precision and durability.

Skilled professionals delivering top-quality results.

From design to fabrication and installation.

Cost-effective welding solutions for all industries.

Serving petroleum, food processing, and chemical sectors.

How to Choose the Best Tank Welding Company?

When selecting from the many tank welding companies, consider the following factors:

- Experience & Expertise – Choose a company with a proven track record like Fabrimech.

- Welding Quality & Techniques – Ensure the company follows industry best practices.

- Material Strength & Durability – Opt for high-quality materials for long-lasting tanks.

- Safety & Compliance Certifications – Look for ISO, ASME, and API-approved welding companies.

- Project Customization & Support – A reliable company should offer tailored solutions.

Conclusion

If you’re searching for the best tank fabricating companies, Fabrimech is your ideal choice. With expertise in advanced welding techniques, high-quality materials, and precision engineering, Fabrimech delivers top-notch storage tank solutions for industries of all sizes.

Contact Fabrimech today for high-quality tank welding services tailored to your industrial needs!

Irrigation Water Tanks Manufacturers: A Complete Guide

Introduction

When it comes to efficient water management for agricultural purposes, irrigation water tanks play a crucial role. Farmers and agricultural businesses rely on these tanks to store and distribute water effectively across large farmlands. As the demand for high-quality irrigation systems increases, manufacturers are stepping up to provide durable and cost-effective solutions to meet these needs.

What Are Irrigation Water Tanks?

Irrigation water tanks specially designed containers that store water for agricultural irrigation systems. These tanks help ensure that crops receive consistent and timely water supply, even during periods of drought or when rainfall is insufficient. The best water tanks made from materials that resist corrosion, UV damage, and other environmental factors.

The Role of Irrigation Water Tanks Manufacturers

Irrigation water tanks manufacturers focus on producing tanks that are not only strong and long-lasting but also cater to the diverse needs of farmers. These manufacturers offer a variety of tank sizes, shapes, and materials to suit different irrigation systems. Whether it’s for small-scale farms or large agricultural setups, manufacturers like Fabrimech provide high-quality solutions tailored to specific irrigation requirements.

Why Choose Fabrimech for Irrigation Water Tanks?

When searching for reliable irrigation water tank manufacturers, Fabrimech stands out. Known for its commitment to quality, Fabrimech manufactures tanks are designed to endure extreme weather conditions and are resistant to leaks and cracks. With years of expertise in the field, Fabrimech ensures efficient, durable, and cost-effective water tanks.. Their tanks come in various capacities, making them suitable for different scales of agricultural irrigation. Fabrimech’s water tanks are also customizable, giving farmers the flexibility to choose the right size and design for their specific needs.

Key Benefits of Choosing the Right Irrigation Water Tank

- Durability: High-quality water tanks built to last, ensuring long-term performance even in harsh environmental conditions.

- Cost-Effectiveness: Investing in reliable tanks reduces the need for constant repairs and replacements, which can save money in the long run.

- Flexibility: Fabrimech offer a variety of options can be tailored to specific irrigation needs, making it easier to manage water resources efficiently.

Conclusion

If you’re looking for a trusted partner in irrigation systems, choosing the right irrigation water tanks manufacturers is essential. Companies like Fabrimech provide high-quality, durable, and customizable solutions that help optimize irrigation practices. By investing in the right water tanks, you can ensure that your agricultural operations run smoothly and efficiently, even in challenging conditions.

TOP CHEMICAL STORAGE TANK MANUFACTURERS

Chemical storage tanks are essential for industries dealing with hazardous and non-hazardous chemicals. Choosing the right chemical storage tank manufacturer ensures safety, durability, and compliance with industry regulations. Among the top manufacturers, Fabrimech stands out for its high-quality chemical storage tanks, designed to meet diverse industrial storage needs.

Why Choose a Reliable Chemical Storage Tanks Manufacturer?

Investing in high-quality chemical storage tanks is crucial for maintaining safety and efficiency. When selecting a manufacturer, consider the following factors:

- Material Quality: Tanks made from corrosion-resistant steel or specialized plastics enhance durability.

- Customization Options: Leading manufacturers like Fabrimech offer tailored solutions for specific storage requirements.

- Compliance with Industry Standards: Certified chemical storage tanks manufacturers adhere to environmental and safety regulations.

- Capacity and Design: Choosing the right size and structure is vital for optimal storage efficiency.

Fabrimech: A Leading Name in Chemical Storage Tanks

Fabrimech is a well-known manufacturer providing premium chemical storage tanks with advanced engineering and high durability. Their product range includes:

- Above-ground and underground chemical storage tanks

- Double-wall and single-wall designs for enhanced safety

- Custom fabrication to meet specific industry needs

- Corrosion-resistant materials for long-lasting performance

- Regulatory-compliant and environmentally safe solutions

Key Features of Chemical Storage Tanks by Fabrimech

- High-Quality Manufacturing: Fabrimech ensures superior materials for long-lasting durability.

- Cost-Effective Solutions: Their chemical storage tanks offer long-term savings by reducing maintenance costs.

- Industry Compliance: All tanks meet required certifications and safety guidelines.

- Versatile Applications: Suitable for industries such as pharmaceuticals, chemicals, and petroleum.

Conclusion

Selecting the right chemical storage tanks manufacturer is crucial for ensuring safe and efficient chemical storage. Fabrimech provides top-quality chemical storage tanks, offering customized solutions for various industries. Whether you require a small storage unit or a large industrial chemical storage tank, Fabrimech delivers durable, high-performance options to meet your specific needs. For the best chemical storage tanks, trust Fabrimech to provide compliant, cost-effective, and long-lasting storage solutions tailored to your industry.

Oil Storage Tank Manufacturers: Quality, Durability & Reliability

Oil storage tanks are a crucial component in various industries, ensuring the safe and efficient storage of fuel, crude oil, and other petroleum products. Finding the right oil storage tank manufacturer is essential to guarantee quality, durability, and compliance with industry standards. Among the leading names in the industry, Fabrimech stands out for its high-quality storage tank solutions designed to meet diverse storage needs.

Why Choose a Reliable Oil Storage Tank Manufacturer?

A well-manufactured oil storage tank ensures safety, longevity, and efficient fuel management. When selecting a manufacturer, consider factors such as:

- Material Quality: Tanks made from premium-grade steel or fiberglass last longer and withstand harsh conditions.

- Customization Options: Leading manufacturers like Fabrimech offer customized solutions tailored to specific industry requirements.

- Compliance with Industry Standards: A certified oil storage tank manufacturer ensures adherence to safety and environmental regulations.

- Capacity and Design: Whether for industrial, commercial, or agricultural use, choosing the right size and design is crucial.

Fabrimech : A Trusted Name in Oil Storage Tanks

Fabrimech has earned a reputation as a leading manufacturer of oil storage tanks known for their durability and advanced engineering. The company offers:

- Above-ground and underground oil storage tanks

- Double-wall and single-wall designs

- Custom fabrication for unique storage requirements

- Corrosion-resistant coatings for extended lifespan

- Compliant and environmentally friendly solutions

Benefits of Choosing Fabrimech for Oil Storage Tanks

- High-Quality Manufacturing: Fabrimech ensures the use of top-grade materials, enhancing tank longevity.

- Cost-Effective Solutions: Their oil storage tanks are designed to provide long-term savings by reducing maintenance and enhancing efficiency.

- Industry Compliance: All tanks meet the required industry certifications and safety standards.

- Versatile Applications: Suitable for industries like petroleum, chemical, and agriculture.

Conclusion

Selecting the right oil storage tank manufacturer is essential for ensuring safety, durability, and cost-efficiency. Fabrimech has established itself as a reliable provider of premium oil storage tanks, meeting the needs of various industries with customized, high-quality solutions. Whether you need a small storage unit or a large industrial-grade, choosing a trusted manufacturer like Fabrimech ensures long-lasting and efficient performance. If you are looking for the best oil storage tank solutions, consider Fabrimech for high-quality, compliant, and durable tanks tailored to your needs.

Ausdehnungsgefäß für Heizungs- und Kühlsysteme: Funktion, Typen und Auswahl

Ausdehnungsgefäß für Heizungs- und Kühlsysteme: Funktion, Typen und Auswahl

Ein Ausdehnungsgefäß ist ein unverzichtbarer Bestandteil geschlossener Heizungs- und Kühlsysteme. Es sorgt für einen sicheren und effizienten Betrieb, indem es Druckschwankungen ausgleicht, die durch Temperaturschwankungen im System entstehen. In diesem Artikel erfahren Sie mehr über die Funktion, die verschiedenen Typen und die Kriterien für die Auswahl des richtigen Ausdehnungsgefäßes.

Die Funktion eines Ausdehnungsgefäßes

Das Ausdehnungsgefäß hat die Aufgabe, den Druck im System konstant zu halten, indem es das Volumen des Wassers oder der Kühlflüssigkeit bei Temperaturschwankungen ausgleicht.

- Heizsysteme: In Heizungsanlagen dehnt sich das Wasser bei Erwärmung aus und erhöht den Druck im System. Das Ausdehnungsgefäß nimmt das zusätzliche Volumen auf und verhindert Schäden wie Lecks oder Rohrbrüche.

- Kühlsysteme: In Kühlsystemen funktioniert das Prinzip ähnlich, nur dass die Flüssigkeit bei Temperatursenkungen kontrahiert. Auch hier wird der Druckausgleich durch das Ausdehnungsgefäß sichergestellt.

Typen von Ausdehnungsgefäßen

Es gibt verschiedene Typen von Ausdehnungsgefäßen, die je nach Anwendung und Systemanforderungen eingesetzt werden.

Membranausdehnungsgefäße:

- Diese sind die gängigsten Typen. Eine flexible Membran trennt die Gas- und Flüssigkeitskammer.

- Vorteile: Lange Lebensdauer, wartungsarm und für verschiedene Systeme geeignet.

- Anwendung: Heizungs-, Kühlsysteme und Solaranlagen.

Offene Ausdehnungsgefäße:

- Werden in älteren Systemen eingesetzt. Sie benötigen keinen Druck und sind direkt mit der Umgebungsluft verbunden.

- Nachteil: Höherer Wartungsaufwand, da das Wasser verdunsten kann.

Industrielle Ausdehnungsgefäße:

- Speziell für große oder komplexe Anlagen, z. B. in der Industrie oder in HVAC-Systemen.

- Diese Gefäße sind häufig EN 15085-2 zertifiziert, was eine hohe Qualität und Sicherheit gewährleistet.

Auswahl des richtigen Ausdehnungsgefäßes

Die Wahl des richtigen Ausdehnungsgefäßes hängt von mehreren Faktoren ab:

Systemdruck und Volumen:

- Berechnen Sie den Druckbereich und das Volumen der Anlage, um die richtige Größe des Gefäßes zu bestimmen.

Anwendungsbereich:

- Für Heizungsanlagen sollten Sie Gefäße wählen, die speziell für hohe Temperaturen geeignet sind.

- Für Kühlsysteme sind Gefäße mit niedrigen Druckbereichen besser geeignet.

Zertifizierungen:

- Achten Sie auf Standards wie EN 15085-2 für industrielle Anwendungen, um eine hohe Qualität und Sicherheit zu gewährleisten.

Wartung und Langlebigkeit:

- Wählen Sie ein wartungsarmes Gefäß mit langer Lebensdauer, um langfristige Kosten zu senken.

Die Vorteile eines hochwertigen Ausdehnungsgefäßes

- Schutz vor Druckschäden – Verhindert Schäden an Rohren, Ventilen und anderen Systemkomponenten.

- Effizienter Betrieb – Sorgt für eine gleichmäßige Leistung von Heizungs- und Kühlsystemen.

- Längere Lebensdauer des Systems – Minimiert den Verschleiß und reduziert das Risiko von Ausfällen.

Fazit

Das Ausdehnungsgefäß ist ein wesentlicher Bestandteil von Heizungs- und Kühlsystemen. Seine Funktion, Druckschwankungen auszugleichen, schützt das System vor Schäden und sorgt für eine effiziente und sichere Leistung. Bei der Auswahl eines Ausdehnungsgefäßes sollten Sie Faktoren wie Systemdruck, Anwendungsbereich und Zertifizierungen berücksichtigen. Durch die richtige Wahl eines hochwertigen Gefäßes gewährleisten Sie einen langfristig störungsfreien Betrieb Ihrer Anlage.

Sind Sie auf der Suche nach einem hochwertigen, EN 15085-2 zertifizierten Ausdehnungsgefäß zu einem erschwinglichen Preis?

Fabrimech bietet erstklassige und preiswerte Ausdehnungsgefäße für Heizungs- und Kühlsysteme! Kontaktieren Sie uns jetzt für ein Angebot!