Introduction to Lightweight Aluminium Components

In today’s fast-evolving transportation industry, lightweight aluminium components have become essential for improving performance, fuel efficiency, and sustainability. Chennai, a major manufacturing hub in India, is at the forefront of producing high-quality lightweight aluminium components for various transportation needs — from metro rail coaches to commercial vehicles and electric mobility systems.

What Are Lightweight Aluminium Components?

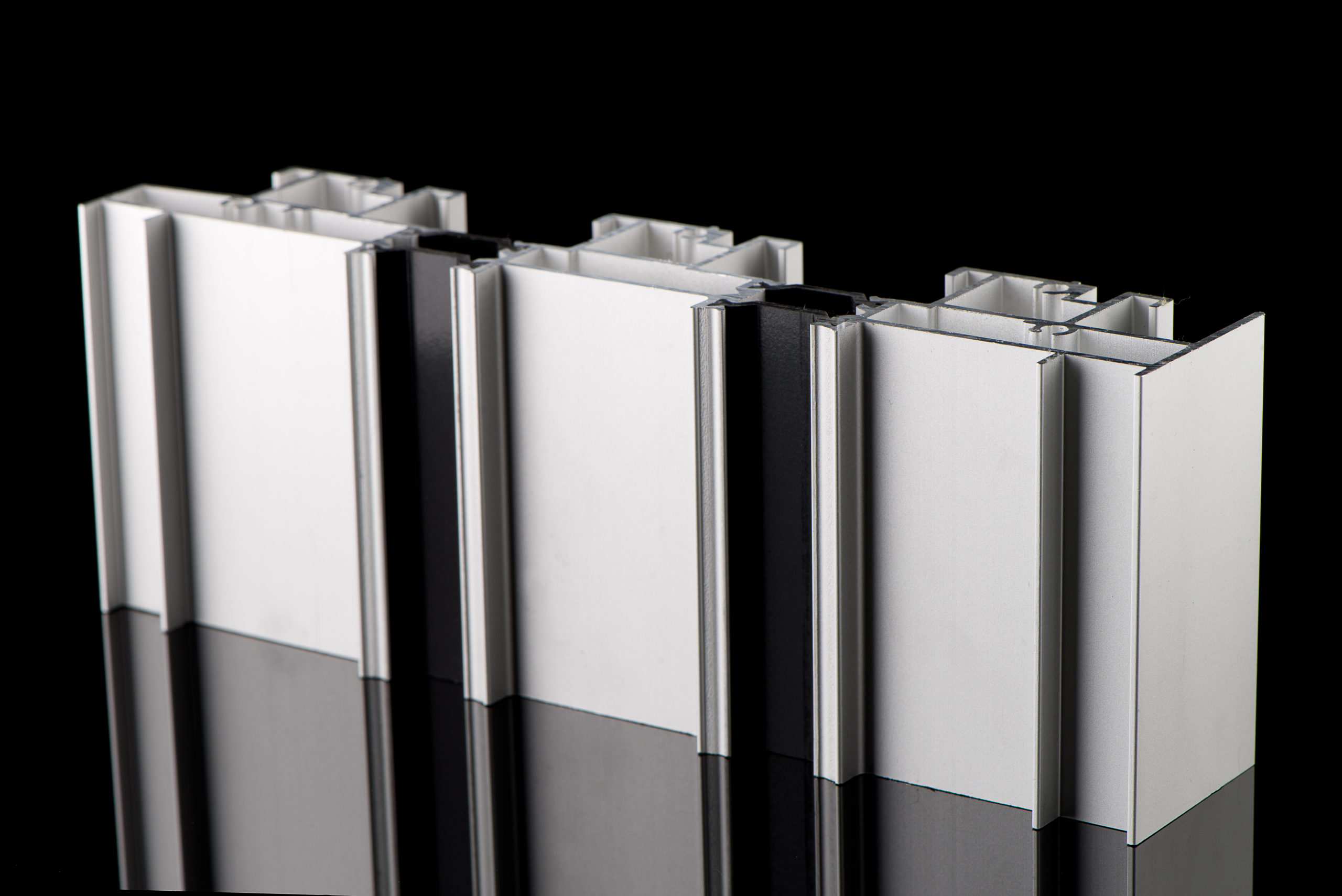

Lightweight aluminium components refer to transport-grade parts and structures made using aluminium and its alloys, known for their high strength-to-weight ratio. These components include structural frames, brackets, flooring systems, doors, panels, and more — all designed to reduce the overall weight of vehicles without compromising on strength and durability.

Why Aluminium Is the Preferred Choice in Transportation

Aluminium is the metal of choice for modern transportation due to the following advantages:

- Lightweight Nature: Up to 60% lighter than steel.

- Corrosion Resistance: Ideal for humid and coastal climates

- Recyclability: 100% recyclable, promoting eco-friendly practices.

- High Strength: Advanced aluminium alloys offer strong mechanical properties.

- Heat and Electrical Conductivity: Useful in EV battery housing and rail systems.

Specifications and Design of Lightweight Aluminium Components

Below is a detailed look at the specifications, capacity, and design shapes used in manufacturing lightweight aluminium components:

| Parameter | Details |

|---|---|

| Material | 6061, 6082, 5052 Aluminium Alloys |

| Shape/Form | Sheets, Tubes, Extrusions, Panels, Angles |

| Weight Reduction | Up to 40% compared to steel parts |

| Thickness Range | 0.5 mm – 12 mm (based on application) |

| Load Bearing Capacity | Up to 10 tonnes (customized engineering design) |

| Surface Finishes | Anodized, Powder Coated, Brushed, or Painted |

| Fabrication Techniques | CNC Machining, TIG/MIG Welding, Laser Cutting, Bending, and Assembly |

| Application Areas | Rail coaches, EVs, buses, trucks, metro interiors, support structures |

Have questions? We’re here to help!

Applications in Chennai’s Transport Ecosystem

Chennai, with its thriving automobile and rail coach industries, is a hotspot for the manufacturing and integration of lightweight aluminium components. These components are widely used in:

- Metro Rail Projects – side panels, flooring, and roof structures.

- Electric Vehicles (EVs) – battery enclosures, frames, and chassis supports.

- Commercial Transport Vehicles – lightweight bodies, cargo bays, and side rails.

- Aerospace and Marine Support – corrosion-resistant panels and interior elements.

The Manufacturing Process

The production of lightweight aluminium components involves precision engineering and advanced fabrication techniques. Manufacturers in Chennai ensure strict adherence to global standards like ISO to meet the demanding quality needs of the transport industry.

Why Choose Fabrimech for Aluminium Component Manufacturing?

At Fabrimech Engineering Pvt. Ltd., we specialize in the design, fabrication, and supply of lightweight aluminium components tailored for India’s growing transportation sector. With our Chennai-based manufacturing facility and decades of engineering excellence, we deliver:

- Custom design solutions

- Precision fabrication with CNC technology

- Lightweight structures meeting ISO certifications

- On-time delivery with nationwide support

Partner with Fabrimech today for reliable, durable, and efficient lightweight aluminium components that move your business forward.

Contact Us to discuss your next transportation project!