3 Point Bending: Principles and Applications | Fabrimech Engineers Pvt Ltd

In the world of material testing, 3 point bending is a widely used technique to evaluate the mechanical properties of materials, especially in terms of their flexural strength and stiffness. This method is commonly used in industries such as construction, aerospace, and manufacturing. One leading company specializing in precision bending and testing solutions is Fabrimech. Let’s explore the fundamentals of bending, its applications, and why it’s a critical process in material testing.

What is 3 Point Bending?

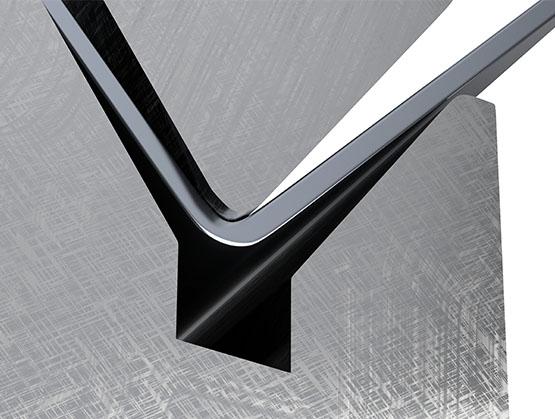

3 point bending is a <astyle=”color:#696969;” href=”https://www.sciencedirect.com/topics/engineering/three-point-bending-test”>mechanical test in which a sample is supported at two points while a force is applied at the center to measure its resistance to bending. The setup consists of:

-

Two support points at a fixed distance apart

-

A central loading point where force is applied

-

A testing machine that records the force required to bend or break the sample

This test provides critical data on material behavior under stress, helping engineers and researchers determine material properties such as flexural modulus and fracture toughness.

Applications of 3 Point Bending

The 3 point bending test is widely used across various industries, including:

-

Construction and Civil Engineering – To assess the strength of concrete, beams, and structural components.

-

Aerospace – Ensuring the durability of composite materials used in aircraft and spacecraft.

-

Automotive – Testing the strength of car frames, suspension parts, and composite panels.

-

Manufacturing and Fabrication – Companies like Fabrimech utilize 3 point bending to verify the quality of metal and plastic components in industrial applications.

-

Medical Devices – Ensuring the flexibility and strength of prosthetic devices and implants.

Have questions? We’re here to help!

Why Choose Fabrimech for 3 Point Bending Solutions?

Fabrimech is a trusted name in material testing and fabrication. Their expertise in 3 point bending allows manufacturers to ensure that their materials meet industry standards. With state-of-the-art equipment and experienced professionals, Fabrimech provides precise and reliable testing solutions that help businesses optimize their product performance.

Benefits

- Accurate Material Analysis – Helps in understanding the flexural strength and elasticity of materials.

-

Cost-Effective – A simple yet effective way to test mechanical properties without complex procedures.

-

Versatile Testing Method – Can be applied to metals, plastics, composites, and ceramics.

-

Quality Assurance – Ensures that materials used in critical applications meet safety and performance standards.

Conclusion

3 point bending plays a crucial role in material testing, offering valuable insights into the strength and durability of various materials. Whether in aerospace, construction, or manufacturing, this method helps industries produce safer and more reliable products. In Chennai, India, companies like Fabrimech provide advanced bending solutions to ensure high-quality standards and strict industry compliance. Investing in proper material testing is essential for innovation and long-term success in any industry.

If you are looking for expert bending services in Chennai, India, consider partnering with Fabrimech for precise and reliable testing solutions.